A running toilet isn’t just an annoying noise – it’s a costly problem that can waste hundreds of gallons of water and significantly increase your utility bills[1]. This comprehensive guide will help you diagnose and fix your running toilet using simple DIY solutions.

Common Causes of a Running Toilet

A toilet that won’t stop running typically stems from issues within the tank components. The most frequent causes include:

- Faulty flapper not creating a proper seal

- Incorrect float height adjustment

- Damaged fill valve

- Chain problems

- Mineral buildup or debris

- High water pressure[2]

Initial Troubleshooting Steps

Before diving into specific repairs, follow these essential first steps:

- Remove the tank lid carefully and set it aside

- Observe the water level (should be 1-inch below overflow tube)

- Check if the flapper is sealing properly

- Inspect the chain length and connection

- Look for visible damage to components[3]

Essential Tools and Materials

To fix your running toilet, you’ll need:

| Tool/Material | Purpose |

|---|---|

| Adjustable pliers | Tightening connections |

| Screwdriver | Removing/installing parts |

| Replacement flapper | If old one is worn |

| Fill valve | If adjustment fails |

| Rubber gloves | Protection during work |

| Bucket | Catching excess water |

Diagnosing Specific Problems

The Flapper Issue

The flapper is the most common culprit in running toilets. This rubber seal prevents water from continuously flowing from the tank into the bowl. Signs of a faulty flapper include:

- Visible warping or deterioration

- Mineral buildup on the sealing surface

- Chain that’s too short or too long

- Improper alignment with the flush valve opening

Testing the Flapper

- Add a few drops of food coloring to the tank water

- Don’t flush for 30 minutes

- If the bowl water changes color, your flapper isn’t sealing properly

Float Adjustment Problems

The float controls the water level in your tank. Two common types exist:

| Float Type | Characteristics | Adjustment Method |

|---|---|---|

| Ball Float | Connected to arm | Bend arm or adjust screw |

| Cup Float | Slides up/down | Squeeze clip and adjust height |

Fill Valve Complications

A malfunctioning fill valve can cause continuous running or irregular filling patterns. Common symptoms include:

- Hissing sounds

- Water trickling into overflow tube

- Inconsistent water level

- Slow tank filling

Step-by-Step Repair Guide

Replacing a Faulty Flapper

- Turn off water supply

- Flush toilet to empty tank

- Disconnect chain from flush lever

- Remove old flapper

- Clean flush valve seat

- Install new flapper

- Reconnect chain with proper slack

- Turn water back on and test

Here’s the third chunk:

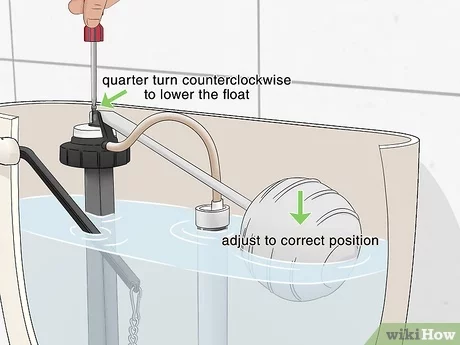

Adjusting the Fill Valve

The fill valve requires precise adjustment to prevent overflow issues. Follow these steps:

- Locate the adjustment screw or clip

- Mark ideal water level (1 inch below overflow tube)

- Adjust until water stops at marked level

- Test flush several times to verify

Critical Measurements

- Optimal water level: 1-inch below overflow tube

- Chain slack: 1/2 inch

- Float height: Typically 7-8 inches from tank bottom

Advanced Troubleshooting

Water Pressure Issues

High water pressure can cause persistent running. Signs include:

- Forceful tank filling

- Overflow tube splashing

- Quick fill cycles

Solutions:

- Install a water pressure reducer

- Adjust the supply valve

- Replace with pressure-compensating fill valve

Mineral Buildup Solutions

In areas with hard water, mineral deposits can affect toilet function:

| Treatment Method | Application | Frequency |

|---|---|---|

| Vinegar Soak | Components | Every 6 months |

| CLR Treatment | Severe buildup | As needed |

| Prevention Tablets | Tank water | Monthly |

Professional vs. DIY Repair

Consider professional help if:

- Multiple components need replacement

- Crack detection in porcelain

- Persistent issues after DIY attempts

- Complex plumbing modifications needed

Preventive Maintenance

Regular maintenance can prevent running toilet issues and extend component life.

Monthly Checks

- Inspect flapper for deterioration

- Clean mineral deposits

- Check water level

- Test flush performance

- Listen for unusual sounds

Seasonal Maintenance

Spring/Summer Tasks:

- Deep clean tank components

- Check for condensation issues

- Inspect supply line condition

Fall/Winter Tasks:

- Insulate tank if needed

- Check for freeze prevention

- Verify proper heating circulation

Cost Implications

Water Waste Calculator

A running toilet can waste significant amounts of water:

| Severity | Gallons Per Day | Monthly Cost Impact |

|---|---|---|

| Minor Leak | 30-50 | $5-10 |

| Moderate Run | 200-300 | $30-45 |

| Severe Issue | 600-800 | $90-120 |

Repair Costs

DIY Repairs:

- Basic flapper replacement: $5-15

- Fill valve kit: $15-25

- Complete rebuild kit: $30-50

Professional Service:

- Basic service call: $75-150

- Complete rebuild: $200-400

- Emergency service: $300-500

Frequently Asked Questions

Q: How can I tell if my toilet is running without hearing it?

A: Check your water bill for unexpected increases, use food coloring in the tank, or monitor the water level in the bowl over time.

Q: How often should toilet parts be replaced?

A: Most internal components should be replaced every 4-5 years, but flappers may need replacement every 2-3 years.

Q: Can hard water damage toilet components?

A: Yes, mineral buildup from hard water can deteriorate parts and affect proper sealing, requiring more frequent maintenance.

Q: Is a running toilet an emergency?

A: While not typically an emergency, it should be addressed promptly to prevent water waste and potential flooding.

Troubleshooting Decision Tree

Quick Reference Guide

Immediate Actions Based on Symptoms:

- Constant Running → Check flapper first

- Intermittent Running → Inspect float adjustment

- Partial Flushes → Examine chain length

- Tank Overflow → Adjust fill valve height

When to Replace vs. Repair

| Component | Repair If | Replace If |

|---|---|---|

| Flapper | Minor warping | Brittle/torn |

| Fill Valve | Adjustable | Leaking/broken |

| Float | Adjustable | Cracked/waterlogged |

| Chain | Too long/short | Corroded/broken |

Environmental Impact

A running toilet’s environmental footprint extends beyond water waste:

- Increased energy consumption for water treatment

- Higher carbon footprint from water processing

- Strain on municipal water systems

- Potential groundwater impacts

Smart Solutions and Modern Alternatives

Technology Integration

Modern solutions for preventing running toilets:

- Smart water monitors

- Automatic shut-off systems

- Leak detection devices

- Water consumption trackers

Eco-Friendly Options

- Dual-flush conversion kits

- Water-saving flappers

- Pressure-assisted systems

- Smart toilet upgrades

Safety Considerations

Always remember these safety guidelines:

- Turn off water before repairs

- Avoid harsh chemicals

- Use appropriate tools

- Keep work area dry

- Wear protective gear

Citations:

[1] https://www.mrrooter.com/greater-syracuse/about-us/blog/2017/october/what-to-do-if-your-toilet-won-t-stop-running/

[2] https://www.ars.com/blog/how-to-stop-running-toilet

[3] https://www.hgtv.com/how-to/home-improvement/tips-on-solving-common-toilet-problems

[4] https://www.cnet.com/home/smart-home/how-to-fix-a-running-toilet/

[5] https://www.lowes.com/n/how-to/common-toilet-problems