Water hammer arrestors play a crucial role in protecting plumbing systems from damaging pressure surges. Understanding proper sizing is essential for optimal performance and system protection.

Understanding Water Hammer Arrestor Sizing

Water hammer arrestor size refers to the device’s capacity to absorb and control pressure surges in plumbing systems[1]. The sizing is typically measured in fixture units, which represent the load-producing effects of different plumbing fixtures on the system.

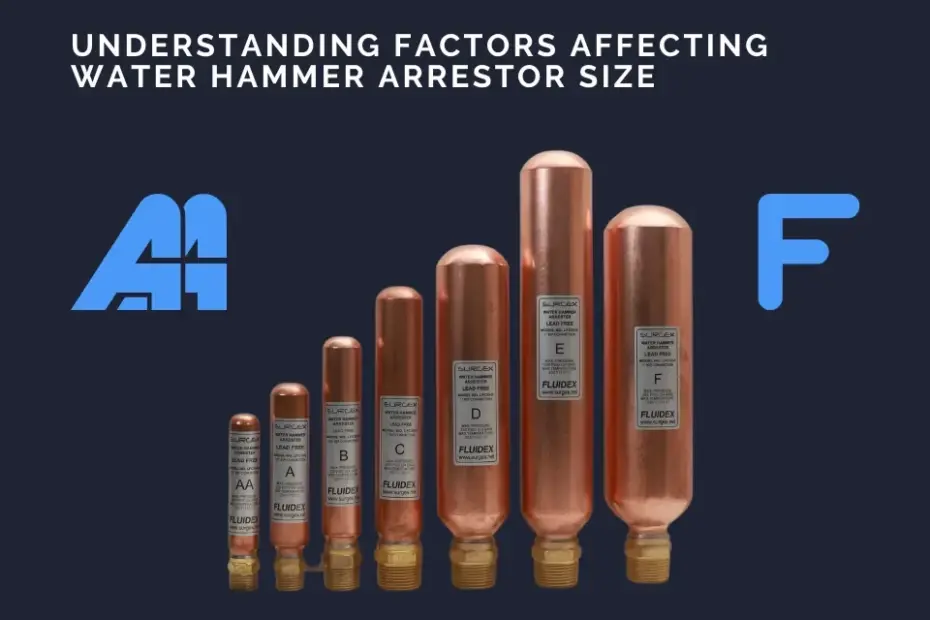

Standard Size Classifications

Water hammer arrestors are classified into standard sizes, typically ranging from AA to F:

| Arrestor Size | Fixture Units |

|---|---|

| AA | 1-4 |

| A | 5-11 |

| B | 12-32 |

| C | 33-60 |

| D | 61-113 |

| E | 114-154 |

| F | 155-300 |

Fixture Unit Values

Different plumbing fixtures have specific fixture unit values that determine arrestor sizing[2]:

Public Fixtures:

- Water Closet (Flush Valve): 8 units

- Pedestal Urinal: 4 units

- Lavatory: 2 units

- Service Sink: 3 units

Private Fixtures:

- Water Closet (Flush Tank): 2.5 units

- Bathtub: 2 units

- Shower Head: 2 units

- Clothes Washer: 4 units

Placement Guidelines

Proper placement is as critical as sizing for effective water hammer control[4]:

Branch Line Installation

For branch lines 20 feet or less:

- Install arrestor within 6 feet of the last fixture

- Place at the end of the branch line

- Use single arrestor sized for total fixture units

For branch lines over 20 feet:

- Calculate fixture units for each 20-foot section

- Place arrestors at the end of each section

- Install within 6 feet of the last fixture in each section

Sizing Calculations and Methodology

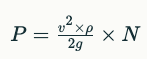

Basic Sizing Formula

The fundamental calculation for water hammer arrestor sizing follows this principle:

Where:

- P = Surge pressure (psi)

- v = Flow velocity (ft/sec)

- ρ = Fluid density

- g = Gravitational constant

- N = System coefficient

Flow Rate Considerations

The sizing must account for various flow rates:

| Pipe Size (inches) | Max Flow Rate (GPM) | Recommended Arrestor |

|---|---|---|

| 1/2 | 1-10 | AA or A |

| 3/4 | 11-20 | A or B |

| 1 | 21-30 | B or C |

| 1-1/4 | 31-45 | C or D |

| 1-1/2 | 46-60 | D or E |

System Pressure Factors

Pressure considerations affect sizing in the following ways:

- Working pressure below 65 psi: Use standard sizing chart

- Working pressure 65-80 psi: Increase one size

- Working pressure above 80 psi: Increase two sizes or consult manufacturer

Temperature Adjustments

Temperature impacts require the following adjustments:

- Cold water (40°F-80°F): Standard sizing

- Hot water (81°F-140°F): Increase one size

- Very hot water (>140°F): Increase two sizes

Installation Requirements

Mounting Specifications

Proper mounting ensures optimal performance:

- Vertical installation preferred

- Horizontal installation acceptable if manufacturer approved

- Minimum clearance of 12 inches from heat sources

- Support weight according to manufacturer specifications

Special Applications and Considerations

Commercial Applications

Commercial installations require specific considerations due to higher usage patterns:

High-Traffic Facilities:

- Hotels: Calculate peak usage periods

- Hospitals: Account for critical care areas

- Schools: Consider simultaneous fixture usage

- Industrial: Factor in equipment-specific requirements

Quick-Closing Valve Protection

Systems with quick-closing valves need special attention:

| Valve Type | Closure Time | Required Protection |

|---|---|---|

| Solenoid | 0.1 sec | Size up by 2 |

| Ball | 0.3 sec | Size up by 1 |

| Gate | 1.0+ sec | Standard size |

Multi-Story Buildings

Height considerations affect sizing requirements:

- Add one size for every 50 feet of elevation

- Install intermediate arrestors every 4-5 floors

- Account for pressure zones in tall buildings

Maintenance and Inspection

Service Life Indicators

Monitor these signs for replacement needs:

- Audible water hammer despite arrestor presence

- Visible corrosion or damage

- Age exceeding manufacturer recommendations

- Decreased effectiveness over time

Performance Testing

Regular testing should include:

- Annual pressure testing

- Quarterly visual inspections

- Monthly operation verification

- Documentation of all maintenance activities

Troubleshooting Guide

Common issues and solutions:

| Problem | Possible Cause | Solution |

|---|---|---|

| Continuous hammering | Undersized arrestor | Upgrade size |

| Partial protection | Poor placement | Relocate device |

| No effect | Failed unit | Replace unit |

Advanced System Integration

Smart Building Integration

Modern building management systems incorporate water hammer protection:

- Real-time pressure monitoring

- Automated maintenance alerts

- Data logging for system optimization

- Integration with building automation

Key Takeaways

Water hammer arrestor sizing requires careful consideration of multiple factors including fixture units, system pressure, and installation location. Proper sizing ensures optimal protection and system longevity.

Frequently Asked Questions

Q: How do I determine the right size water hammer arrestor for my home?

A: Calculate the total fixture units in your plumbing system using the standard fixture unit values, then refer to the sizing chart to select the appropriate arrestor size (AA-F).

Q: How often should water hammer arrestors be replaced?

A: Water hammer arrestors typically last 5-10 years but should be replaced when showing signs of decreased effectiveness or as recommended by the manufacturer.

Q: Can I install a water hammer arrestor horizontally?

A: Yes, horizontal installation is acceptable if specifically approved by the manufacturer, though vertical installation is generally preferred.

Q: Do I need multiple water hammer arrestors in my system?

A: Multiple arrestors may be necessary for branch lines over 20 feet, multiple stories, or systems with numerous fixtures.

Q: Will an undersized water hammer arrestor cause damage?

A: Yes, an undersized arrestor may not adequately protect against pressure surges, potentially leading to pipe damage and system failure.

Citations:

[1] https://www.surgex.net/post/understanding-water-hammer-arrestor-size-importance-and-considerations

[2] https://www.siouxchief.com/docs/default-source/technical-documents/other/supply/HydraRester—Sizing-Placement-Guide

[3] https://www.mifab.com/Catalog/Library/WHA-Guide.pdf

[4] https://www.siouxchief.com/docs/default-source/technical-documents/other/supply/water-hammer-arresters—engineer-report3c4c5a0f83106b288831ff0000b65710.pdf?sfvrsn=405c3137_36

[5] https://valveandmeter.com/blog/marketing/plumbing/keywords/

[6] https://blackstormdesign.com/how-to-pick-the-right-plumbing-seo-keywords-for-your-business-tricks-and-tips/

[7] https://www.digitalsuccess.us/blog/free-seo-keyword-research-50-most-popular-plumbing-services-keywords-in-the-usa.html