Water hammer in hot water systems is a common yet concerning plumbing issue that occurs when the flow of hot water is suddenly interrupted. This phenomenon creates a distinctive banging noise and potentially damaging pressure waves throughout your plumbing system.

Understanding Hot Water Hammer

Hot water hammer differs from cold water hammer primarily due to thermal expansion and contraction. When hot water flows through pipes, they expand slightly. Upon sudden valve closure, the combination of pressure waves and thermal contraction creates more intense hammering effects.

Primary Causes in Hot Water Systems

The main triggers of hot water hammer include:

Quick-closing Valves: Washing machines, dishwashers, and modern faucets with fast-acting valves are common culprits[2][3].

High Water Pressure: Systems operating above 50 PSI are particularly susceptible to water hammer effects.

Thermal Expansion: Hot water expands pipes, creating additional stress when flow suddenly stops.

Impact on Plumbing Systems

Hot water hammer can cause several issues:

- Loosened pipe connections

- Damaged valve seats and washers

- Weakened pipe joints

- Accelerated wear on water heaters

- Compromised pipe integrity

Prevention and Solutions

Several effective methods exist to address hot water hammer:

Immediate Solutions

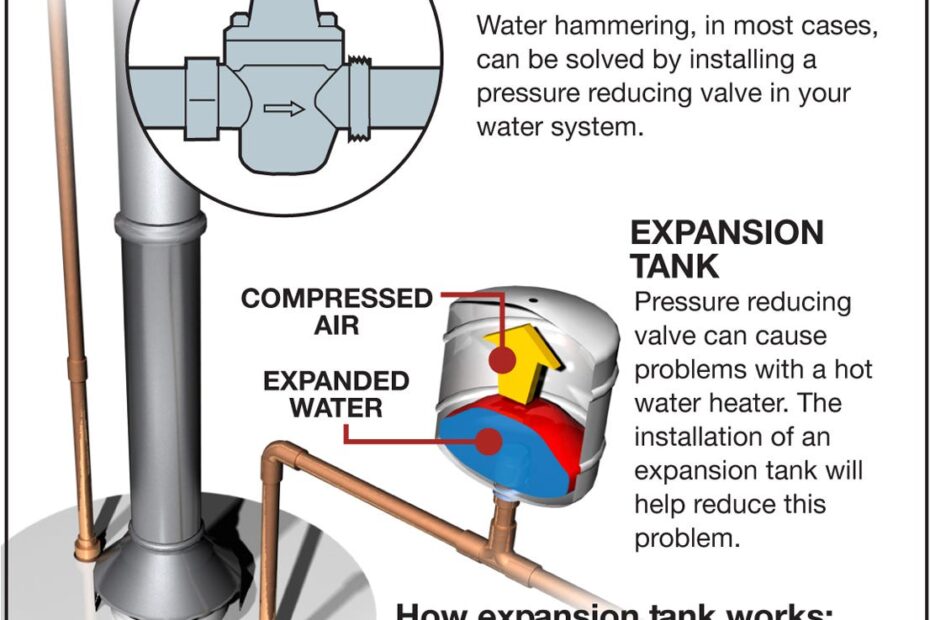

- Pressure Reduction: Install a pressure-reducing valve to maintain pressure below 50 PSI.

- Air Chamber Installation: Install vertical air chambers near problem valves to absorb shock waves.

- Pipe Securing: Ensure all hot water pipes are properly secured with appropriate straps.

Long-term Fixes

Water Hammer Arrestors: These devices provide permanent protection by using a spring-loaded piston to absorb shock waves[2][3].

| Arrestor Type | Effectiveness | Maintenance Required |

|---|---|---|

| Spring-loaded | High | Minimal |

| Air Chamber | Medium | Regular |

| Mechanical | Very High | Annual |

Thermal Dynamics and Water Hammer

Understanding the thermal aspects of water hammer helps explain why it’s more prevalent in hot water systems. Hot water creates unique challenges due to its physical properties and behavior in plumbing systems.

Temperature Effects on Pipes

The relationship between temperature and pipe materials plays a crucial role:

Copper Pipes: Experience greater expansion and contraction cycles, making them more susceptible to water hammer.

PEX Tubing: Shows better resistance to thermal expansion but can still experience significant pressure waves.

Pressure Wave Mechanics

Hot water hammer creates pressure waves that can reach intensities of up to 1500 PSI, far exceeding normal operating pressures. These waves travel through pipes at speeds approaching:

- Copper pipes: 4,000 feet per second

- PVC pipes: 2,400 feet per second

- PEX tubing: 1,800 feet per second

System Design Considerations

Proper system design can significantly reduce hot water hammer:

Pipe Sizing: Correctly sized pipes help minimize velocity-related pressure waves.

Layout Planning: Strategic placement of:

- Vertical risers

- Horizontal runs

- Support brackets

- Expansion joints

Temperature Control Measures

Maintaining appropriate water temperatures helps prevent excessive thermal expansion:

| Temperature Range | Effect on System | Risk Level |

|---|---|---|

| 120-130°F | Optimal | Low |

| 130-140°F | Moderate | Medium |

| Above 140°F | High Risk | Severe |

Diagnostic and Troubleshooting Guide

Identifying the specific cause of hot water hammer requires systematic evaluation. Understanding the symptoms and their relationship to system components enables effective troubleshooting.

Common Symptoms Analysis

Location-Based Symptoms:

- Near water heater: Indicates possible thermal expansion issues

- At specific fixtures: Suggests valve-related problems

- Throughout system: Points to pressure regulation issues

Professional Assessment Methods

Modern plumbers use several diagnostic tools:

Pressure Testing: Using calibrated gauges to measure:

- Static pressure

- Dynamic pressure

- Peak pressure during hammer events

Thermal Imaging: Identifies:

- Hot spots

- Expansion points

- Areas of stress concentration

DIY Inspection Points

Homeowners can perform basic checks:

- Listen for timing of hammer sounds

- Note which fixtures trigger the problem

- Monitor water heater temperature settings

- Check visible pipe supports and straps

Maintenance and Prevention Strategies

Regular Maintenance Schedule

| Component | Inspection Frequency | Maintenance Task |

|---|---|---|

| Air Chambers | 6 months | Drain and recharge |

| Arrestors | Annual | Check functionality |

| Pipe Supports | Quarterly | Tighten and adjust |

| Pressure Valves | Semi-annual | Clean and test |

System Modifications

Retrofit Solutions:

- Installing flexible connectors

- Adding expansion tanks

- Upgrading valve types

- Implementing smart pressure controls

Advanced Solutions and Modern Technologies

The evolution of plumbing technology has introduced sophisticated solutions for managing hot water hammer, incorporating smart systems and innovative materials.

Smart Water Management Systems

Modern solutions include:

Electronic Pressure Monitoring:

- Real-time pressure tracking

- Automated valve control

- Early warning systems

- Data logging capabilities

Material Innovations

Recent developments in pipe materials offer better hammer resistance:

Composite Materials:

- Enhanced thermal stability

- Better pressure wave absorption

- Reduced expansion coefficients

- Longer service life

Frequently Asked Questions

Q: Why does water hammer occur only in hot water pipes?

A: Hot water pipes experience more expansion and contraction, making them more susceptible to pressure waves when flow is suddenly stopped.

Q: Can water hammer damage my water heater?

A: Yes, repeated water hammer can damage internal components of water heaters, reducing their lifespan and efficiency.

Q: How much does it cost to fix hot water hammer?

A: Solutions range from $50 for DIY installations of simple arrestors to $500+ for professional system modifications.

Cost Analysis and ROI

Investment Considerations

| Solution Type | Initial Cost | Long-term Savings | Lifespan |

|---|---|---|---|

| Basic Arrestor | $30-100 | Moderate | 5-7 years |

| Professional System | $400-800 | High | 15-20 years |

| Smart System | $1000+ | Very High | 20+ years |

Energy Efficiency Impact

Properly managed hot water systems show:

- 15% reduction in heat loss

- 20% improvement in system efficiency

- Extended equipment lifespan

Long-term System Health and Sustainability

Understanding the relationship between hot water hammer and overall system longevity is crucial for maintaining sustainable plumbing systems.

Environmental Considerations

Energy Conservation:

- Reduced heat loss through proper insulation

- Optimized flow patterns

- Minimized system stress

Future-Proofing Your System

Implementing forward-thinking solutions:

- Modular components for easy upgrades

- Smart monitoring integration

- Scalable pressure management

Key Takeaways

Hot water hammer requires a comprehensive approach to management, combining proper system design, regular maintenance, and appropriate technological solutions. Understanding the unique challenges of hot water systems helps in implementing effective preventive measures and maintaining system integrity.

Professional Recommendations

“Regular maintenance and proper system design are far more cost-effective than emergency repairs caused by water hammer damage.” – Professional Plumbing Association

Safety Considerations

Critical Warning Signs:

- Persistent banging sounds

- Visible pipe movement

- Leaks at joints

- Irregular water pressure