Water hammer is a significant plumbing issue that can cause extensive damage to pipe systems. Understanding the difference between traditional air chambers and modern water hammer arrestors is crucial for effective water hammer prevention and mitigation.

Understanding Water Hammer Protection Devices

Water hammer occurs when flowing water suddenly stops or changes direction, creating a pressure surge that can damage plumbing systems. Two main devices have been developed to address this issue: air chambers and water hammer arrestors.

Traditional Air Chambers

Air chambers are simple vertical pipe extensions installed near plumbing fixtures that act as shock absorbers for water pressure surges[2]. These chambers consist of a capped length of pipe that traps air, creating a cushion to absorb hydraulic shock when water flow stops abruptly.

Key Characteristics of Air Chambers:

- Simple vertical pipe design

- Typically installed within 6 feet of fixtures

- Relies on trapped air for shock absorption

- Requires periodic maintenance

- More affordable initial cost

Modern Water Hammer Arrestors

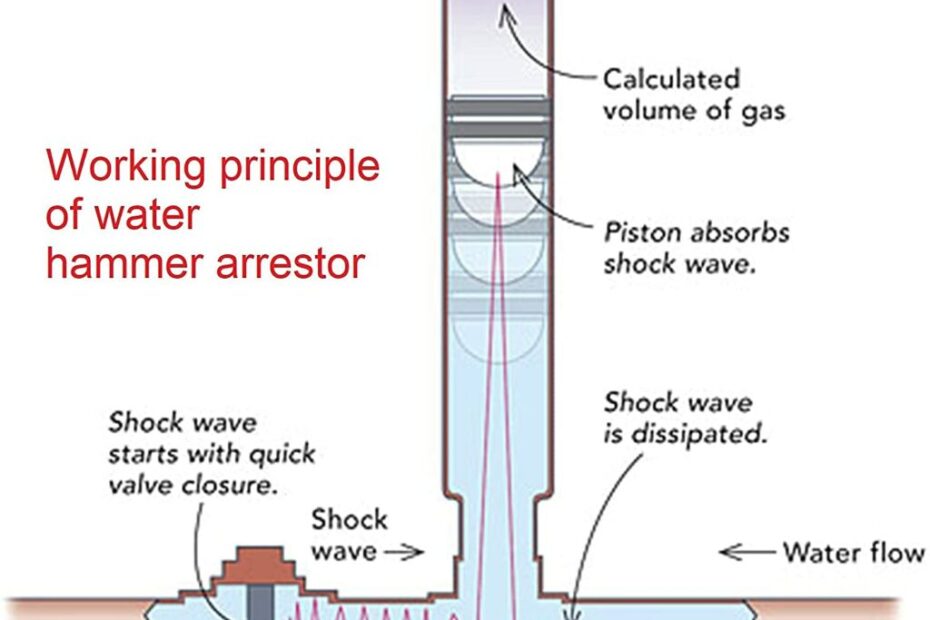

Water hammer arrestors represent a significant advancement in hydraulic shock protection. These devices use sealed air chambers with pistons or bellows to provide consistent protection against water hammer[1].

Features of Water Hammer Arrestors:

- Pre-charged sealed design

- Maintenance-free operation

- Enhanced durability

- Consistent performance

- Better pressure control

Comparative Analysis

| Feature | Air Chambers | Water Hammer Arrestors |

|---|---|---|

| Design | Simple pipe extension | Sealed chamber with piston/bellows |

| Maintenance | Regular draining required | Maintenance-free |

| Longevity | Limited | Extended |

| Performance | Degrades over time | Consistent |

| Cost | Lower initial cost | Higher initial cost |

Installation and Maintenance Requirements

Air Chamber Installation

Air chambers require specific installation considerations to function effectively. The installation process involves careful planning and precise execution to ensure optimal performance.

Installation Guidelines:

- Must be installed vertically

- Minimum length should be 12-15 inches

- Should be sized according to pipe diameter

- Requires accessibility for maintenance

- Best installed during initial plumbing setup

Water Hammer Arrestor Installation

Modern water hammer arrestors offer more flexibility in installation locations and orientations, making them increasingly popular among professional plumbers.

Installation Advantages:

- Can be installed in any orientation

- Available in various sizes for different applications

- Pre-sized units eliminate guesswork

- Can be retrofitted to existing systems

- Multiple mounting options available

Performance Analysis

Air Chamber Performance Factors

Air chambers face several challenges that can impact their effectiveness over time:

Common Issues:

- Air can become waterlogged

- Performance decreases gradually

- Requires regular draining

- Temperature fluctuations affect efficiency

- May fail during extreme pressure events

Water Hammer Arrestor Efficiency

Water hammer arrestors maintain consistent performance throughout their lifespan due to their sealed design and mechanical components:

Performance Benefits:

- Maintains consistent air cushion

- Responds quickly to pressure changes

- Works effectively in all temperatures

- Handles repeated shock events

- Provides measurable protection levels

Cost Analysis and Long-Term Value

Initial Investment Comparison

The financial aspect of choosing between air chambers and water hammer arrestors requires careful consideration of both immediate and long-term costs.

Air Chamber Costs:

- Lower material costs

- Simple installation process

- Minimal specialized tools required

- Lower initial investment

- Additional labor costs for maintenance

Water Hammer Arrestor Investment:

- Higher unit cost

- Professional installation recommended

- Specialized sizing requirements

- One-time installation expense

- No ongoing maintenance costs

Long-Term Economic Impact

When evaluating the total cost of ownership, several factors come into play:

| Cost Factor | Air Chambers | Water Hammer Arrestors |

|---|---|---|

| Initial Cost | $15-30 | $30-100 |

| Installation | $50-100 | $75-150 |

| Annual Maintenance | $50-200 | $0 |

| Lifespan | 3-5 years | 10-15 years |

| Replacement Frequency | More frequent | Rarely needed |

Applications and Use Cases

Residential Applications

Different residential scenarios require specific solutions for water hammer protection:

Single-Family Homes:

- Quick-closing fixtures

- Washing machines

- Dishwashers

- Water heaters

- Outdoor irrigation systems

Multi-Unit Buildings:

- Shared water systems

- High-rise applications

- Multiple fixture protection

- Complex plumbing networks

- High-pressure situations

Technical Specifications and Standards

Industry Standards and Compliance

Both devices must meet specific plumbing codes and standards:

Regulatory Requirements:

- PDI-WH 201 certification for arrestors

- UPC and IPC compliance

- ASSE 1010 standards

- Local building codes

- Manufacturer specifications

Frequently Asked Questions

Q: How long do air chambers last?

A: Air chambers typically last 3-5 years before requiring maintenance or replacement, depending on water quality and usage patterns.

Q: Are water hammer arrestors worth the investment?

A: Yes, water hammer arrestors generally provide better long-term value due to their maintenance-free operation and consistent performance.

Q: Can I install water hammer arrestors myself?

A: While possible, professional installation is recommended to ensure proper sizing and placement for optimal performance.

Key Takeaways

The choice between air chambers and water hammer arrestors depends on various factors including budget, maintenance capability, and specific application requirements. Water hammer arrestors generally offer superior long-term performance and reliability, despite higher initial costs. Air chambers remain a viable option for simple installations and budget-conscious projects, but require regular maintenance to maintain effectiveness.

Citations:

[1] https://maheshvalves.com/what-are-the-benefits-of-a-pre-charged-sealed-air-chamber-in-a-water-hammer-arrestor/

[2] https://plumbingreview.net/what-is-an-air-chamber-in-plumbing/

[3] https://www.phcppros.com/articles/2634-water-hammer-arrestors

[4] https://www.mdpi.com/2071-1050/15/12/9730

[5] https://www.reddit.com/r/Plumbing/comments/pgubg5/water_hammer_arrestors_vs_air_chambers/

[6] https://www.geminivalve.com/water-hammer/