When it comes to plumbing connections and sealing joints, three primary materials dominate the field: pipe dope, plumber’s putty, and Teflon tape. Each serves distinct purposes and has specific applications where it excels. Understanding their differences is crucial for successful plumbing work.

Basic Definitions and Compositions

Pipe Dope

Pipe dope, also known as pipe joint compound, is a paste-like substance designed specifically for sealing threaded pipe connections[1]. It typically contains a mixture of oils, solvents, and various fillers that work together to create an effective seal. Modern pipe dopes often incorporate PTFE (polytetrafluoroethylene) for enhanced sealing capabilities[4].

Plumber’s Putty

Plumber’s putty is a soft, pliable sealing compound made from mineral oils, limestone, and talc[2]. It remains malleable over time and is primarily used for creating watertight seals in non-pressurized applications. The putty’s composition allows it to maintain flexibility while providing an effective barrier against water intrusion[3].

Teflon Tape

Teflon tape, or PTFE tape, is a thin, white tape made from polytetrafluoroethylene[7]. It features a unique molecular structure that provides excellent chemical resistance and temperature stability. The tape is designed to wrap around threaded pipe connections, creating a reliable seal while also lubricating the threads[6].

Primary Applications

When to Use Pipe Dope

- Threaded pipe connections under pressure

- Gas line installations

- High-temperature applications

- Metal-to-metal pipe connections[4]

When to Use Plumber’s Putty

- Sink basket strainers

- Faucet bases

- Drain flanges

- Pop-up drain assemblies[2]

When to Use Teflon Tape

- Threaded water line connections

- Shower heads

- Garden hose fittings

- Compression fittings[6]

| Sealant Type | Best For | Temperature Range | Pressure Rating |

|---|---|---|---|

| Pipe Dope | Metal threads | Up to 400°F | High |

| Plumber’s Putty | Non-pressurized | Up to 120°F | Low |

| Teflon Tape | All threads | -70°F to 300°F | Medium |

Performance Characteristics and Limitations

Pipe Dope Performance

Pipe dope excels in creating reliable seals for pressurized systems. Its key advantages include:

- Superior gap-filling properties for irregular thread surfaces

- Chemical resistance to various substances

- Temperature stability across a wide range

- Immediate sealing capability upon application

However, pipe dope also has limitations:

- Can be messy to apply

- May require cleanup after application

- Some formulations may harden over time

- Can be affected by certain chemicals

Plumber’s Putty Characteristics

Plumber’s putty offers unique benefits for specific applications:

- Maintains flexibility for extended periods

- Easy removal when repairs are needed

- No curing time required

- Simple application process

Notable limitations include:

- Not suitable for pressurized connections

- Can stain certain materials like marble or granite

- May dry out if exposed to air

- Limited temperature resistance

Teflon Tape Properties

Teflon tape provides several advantages:

- Clean application with minimal mess

- Excellent lubrication of threads

- Compatible with most pipe materials

- Immediate use after application

Limitations to consider:

- Can tear during application

- Requires proper wrapping technique

- May need multiple layers for effective sealing

- Not suitable for some chemical applications

Teflon Tape or Pipe Dope For PVC

Based on the search results, here’s a comprehensive analysis of using Teflon tape versus pipe dope for PVC:

Manufacturer Recommendations

PVC manufacturers specifically recommend against using Teflon tape on PVC threaded fittings[2][3]. This is because:

- PVC material relaxes under tension

- Teflon tape adds additional stress to the fittings

- It encourages over-tightening of joints

Proper PVC Threading Technique

The correct way to assemble PVC threaded joints is:

- Finger tighten plus 1-2 turns maximum[2]

- Use a proper non-hardening sealant specifically designed for plastic[2]

- Avoid any lubricants that could encourage over-torquing

Problems with Teflon Tape on PVC

Using Teflon tape on PVC can cause several issues:

- Adds unnecessary strain to the joints[2]

- Can lead to splitting of female fittings due to over-tightening[2]

- May create leak paths when joints are mechanically flexed or temperature changes[2]

Pipe Dope Considerations

While traditional pipe dope isn’t ideal for PVC either, there are specific considerations:

- Many pipe dopes contain oils or solvents that can damage plastic[2]

- Only use sealants specifically certified as compatible with PVC[5]

- Like Teflon tape, pipe dope can make joints too slippery and lead to over-torquing[2]

Best Practice

For PVC connections, the recommended approach is to:

- Use a non-hardening sealant specifically designed for plastic fittings[2]

- Ensure proper tightening technique (finger tight plus 1-2 turns)[2]

- Avoid both traditional pipe dope and Teflon tape unless specifically rated for PVC use[5]

Pipe Dope vs Teflon Tape – Natural Gas

For natural gas connections, both pipe dope and Teflon tape can be effective when used correctly[1][3]. However, there are specific considerations for each:

Teflon Tape for Gas Lines

Yellow Teflon tape is specifically designed for gas applications and differs from white tape used for water lines[1]. When using Teflon tape on gas fittings:

- Apply 2-3 turns around the threads

- Wrap in the direction of the thread to prevent unwinding

- Start slightly behind the first thread

- Use only yellow gas-rated tape rated for temperatures up to 550°F[1]

Pipe Dope Characteristics

Pipe dope (thread sealant) offers several advantages for gas line applications:

- Provides a more reliable seal in situations with vibration

- Creates an immediate seal with no cure time for low-pressure applications

- Can be more effective for heavy-duty industrial applications[2][5]

Professional Recommendations

Many professionals recommend using both products together for optimal sealing:

- Apply Teflon tape first

- Follow with pipe dope

- This combination provides maximum protection against leaks[4]

Safety Considerations

When working with gas lines:

- Always shut off the gas supply before beginning work

- Test connections for leaks using soapy water solution

- If unsure, consult a professional plumber or gas technician[1][5]

Best Practices

For the most reliable seal:

- Never use white Teflon tape meant for water on gas lines

- Avoid blocking the inlet of the pipe with sealant

- Don’t over-tighten connections

- Always verify connections with leak testing[3][5]

Installation Techniques and Best Practices

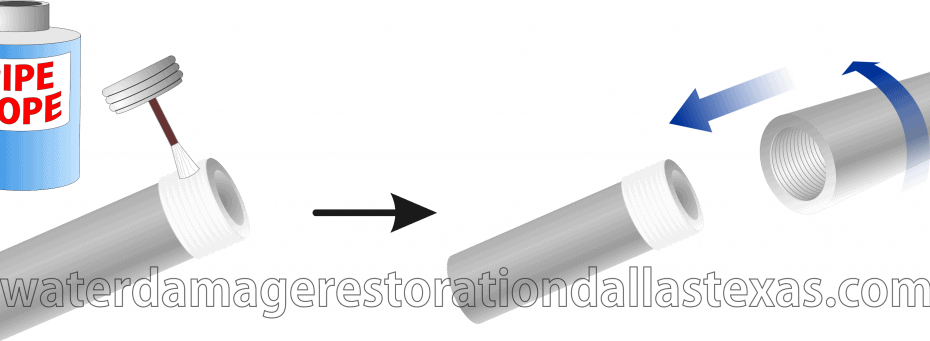

Proper Pipe Dope Application

- Clean threads thoroughly

- Apply thin, even coat to male threads

- Work compound into threads

- Assemble immediately

- Remove excess material

Plumber’s Putty Installation

- Clean surfaces completely

- Roll putty into rope form

- Apply around fixture base

- Install fixture and tighten

- Remove excess putty

Teflon Tape Wrapping Method

- Clean threads thoroughly

- Start at pipe end

- Wrap clockwise 3-4 times

- Maintain tension while wrapping

- Smooth final wrap

Compatibility and Material Considerations

Chemical Compatibility

Different plumbing sealants react differently with various materials and chemicals:

Pipe Dope

- Compatible with most metals including brass, copper, and steel

- Suitable for both water and gas lines

- Some formulations specifically designed for oxygen lines

- May react with certain plastics

Plumber’s Putty

- Works well with most metals

- Avoid use on:

- Natural stone surfaces

- Plastics

- Porous materials

- Can cause staining on certain surfaces

Teflon Tape

- Universal compatibility with most materials

- Special variants available for specific applications:

- Yellow tape for gas lines

- Green tape for oxygen systems

- Pink tape for potable water

Temperature Considerations

| Sealant Type | Minimum Temp | Maximum Temp | Ideal Working Range |

|---|---|---|---|

| Pipe Dope | -30°F | 400°F | 40°F – 350°F |

| Plumber’s Putty | 32°F | 120°F | 50°F – 80°F |

| Teflon Tape | -70°F | 300°F | 35°F – 260°F |

Cost Analysis and Longevity

Cost Comparison

- Pipe Dope:

- Medium initial cost

- Longer shelf life

- More product waste during application

- Plumber’s Putty:

- Low initial cost

- Moderate shelf life

- Minimal waste during application

- Teflon Tape:

- Lowest initial cost

- Indefinite shelf life

- Some waste due to tearing/multiple applications

Longevity and Durability

Pipe Dope Durability

- Typically lasts the lifetime of the connection

- Maintains seal under pressure

- May require reapplication if connection is broken

- Some formulations harden over time

Plumber’s Putty Lifespan

- Remains pliable for extended periods

- May need replacement every 5-10 years

- Can dry out if exposed to air

- Easy to replace when needed

Teflon Tape Endurance

- Indefinite lifespan once properly installed

- Needs replacement if connection is broken

- No degradation over time

- Resistant to most chemicals

Common Problems and Troubleshooting

Pipe Dope Issues

Common Problems

- Over-application leading to clogged pipes

- Insufficient curing time

- Incompatible formulations with pipe material

- Premature drying in container

Solutions

- Apply thin, even coat

- Allow proper curing time per manufacturer specifications

- Verify compatibility before use

- Keep container tightly sealed when not in use

Plumber’s Putty Complications

Frequent Issues

- Staining on porous surfaces

- Drying and cracking

- Inadequate sealing due to improper application

- Putty breaking down due to exposure

Remedies

- Use stain-free formulations for sensitive materials

- Store in airtight container

- Apply adequate amount in continuous bead

- Replace degraded putty during maintenance

Teflon Tape Challenges

Regular Problems

- Incorrect wrapping direction

- Insufficient layers

- Tape tearing during application

- Over-tightening joints

Solutions

- Always wrap clockwise facing pipe end

- Apply 3-4 layers minimum

- Use quality tape and maintain tension

- Hand-tighten plus 1-2 turns with wrench

Professional Tips and Industry Standards

Professional Recommendations

“The key to successful plumbing seals is using the right product for the specific application and following proper installation techniques.” – Master Plumber Association

Best Practices

- Always clean and dry surfaces before application

- Follow manufacturer guidelines strictly

- Consider environmental conditions

- Use appropriate tools for installation

Industry Standards and Codes

Building Codes

- Most jurisdictions follow International Plumbing Code (IPC)

- Specific requirements for gas line sealants

- Potable water system regulations

- Temperature and pressure ratings

Safety Considerations

- Ventilation requirements for pipe dope application

- Material Safety Data Sheet (MSDS) compliance

- proper disposal methods

- Personal protective equipment recommendations

Frequently Asked Questions

Q: Can I use pipe dope and Teflon tape together?

A: While possible, it’s generally unnecessary and may cause over-tightening. Choose one method based on your specific application.

Q: How long should I wait before using a connection sealed with pipe dope?

A: Most pipe dopes allow immediate use, but check manufacturer specifications. Some types require 24-48 hours for optimal curing.

Q: Why does plumber’s putty stain some surfaces?

A: Traditional plumber’s putty contains oils that can leach into porous materials. Use stain-free varieties for natural stone or porous surfaces.

Q: How do I know if I’ve used enough Teflon tape?

A: The threads should be completely covered with 3-4 layers of tape. The valleys between threads should be visible but filled.

Key Takeaways

Choosing the right plumbing sealant depends on various factors including application type, pressure requirements, and material compatibility. Pipe dope offers excellent sealing for pressurized connections, plumber’s putty excels in non-pressurized applications, and Teflon tape provides a clean, reliable seal for threaded connections. Success in plumbing work relies on proper application techniques and understanding each product’s limitations.

Environmental and Safety Considerations

Environmental Impact

- Modern pipe dopes increasingly use eco-friendly formulations

- Proper disposal methods for unused materials

- VOC compliance in different regions

- Recyclability of packaging

Safety Protocols

- Ventilation requirements during application

- Proper storage guidelines

- First aid measures

- Chemical exposure prevention

Citations:

[1] https://www.reddit.com/r/Plumbing/comments/2voxsf/when_to_use_plumbers_putty_or_teflon_tape/

[2] https://www.mrrooter.com/south-jersey/about-us/blog/2023/october/the-comprehensive-guide-to-plumbers-putty/

[3] https://www.mdsewer.com/plumbing/what-plumber-putty

[4] https://terrylove.com/forums/index.php

[5] https://www.cntopa.com/do-you-need-pipe-dope-on-brass-fittings.html

[6] https://blog.qrfs.com/362-how-to-use-pipe-thread-sealant/

[7] https://www.yousantape.com/blog/understanding-teflon-tape-its-uses-characteristics-and-superior-performance.html

[8] https://holscot.com/top-10-advantages-of-teflon-coating-services/

[9] https://community.goodsam.com/t5/rv-newbies/teflon-tape-or-plumbers-putty/td-p/2392394