Water hammer arrestors are essential devices designed to prevent the jarring banging sounds and potential damage caused by water hammer in plumbing systems. However, these devices sometimes fail to resolve the issue, leaving homeowners frustrated and pipes still rattling. Let’s explore why water hammer arrestors might not be working and how to address these challenges effectively.

Common Reasons for Water Hammer Arrestor Failure

Improper Installation

Water hammer arrestors must be installed correctly to function effectively. Common installation issues include:

- Incorrect positioning relative to the problem valve or fixture[1]

- Installation at wrong angles affecting the internal mechanism

- Inadequate securing of surrounding pipes[4]

Undersized Arrestor

Using an arrestor that’s too small for the application can result in continued water hammer issues. The device must be properly sized based on:

- Water pressure levels in the system

- Pipe diameter

- Flow rate requirements[5]

System Pressure Issues

Excessive water pressure can overwhelm even properly installed arrestors. Normal residential water pressure should be:

| Pressure Range | Status |

|---|---|

| 40-60 psi | Optimal |

| 60-80 psi | Acceptable |

| Above 80 psi | Problematic[4] |

Loose Piping

Even with a functioning arrestor, loose pipes can continue to create noise and vibration. Signs include:

- Rattling sounds in walls

- Visible pipe movement

- Persistent banging despite arrestor installation[1]

Initial Troubleshooting Steps

1. Verify Installation

First, ensure the arrestor is:

- Mounted securely

- Installed at the correct angle

- Positioned close to the problem fixture[3]

2. Check Water Pressure

High water pressure can overwhelm arrestors. Install a pressure gauge to verify your system operates within acceptable ranges[4].

3. Inspect Pipe Security

Examine all accessible piping for:

- Loose mounting straps

- Missing supports

- Damaged anchors[6]

Advanced Diagnostic Procedures

System Assessment

Before replacing an arrestor, conduct a thorough evaluation of your plumbing system. Key areas to examine include:

- Main supply lines and their connection points

- Branch line configurations and support structures

- Fixture shutoff valves and their operational status

Air Chamber Evaluation

Many older homes use air chambers instead of mechanical arrestors. These can become waterlogged and ineffective over time. Signs of waterlogged air chambers include:

- Increased frequency of water hammer

- Gradual deterioration of noise reduction

- Complete loss of shock absorption capability

Professional Testing Methods

Professional plumbers typically employ several testing methods:

| Test Type | Purpose | Expected Outcome |

|---|---|---|

| Pressure Testing | Identify system pressure issues | Consistent readings within range |

| Flow Rate Analysis | Determine proper arrestor sizing | Matches fixture requirements |

| Acoustic Testing | Locate exact hammer sources | Pinpoint problem areas |

Replacement Considerations

When to Replace

Consider replacing your water hammer arrestor when:

- The device is more than 5-7 years old

- Visual inspection shows damage or corrosion

- Multiple troubleshooting attempts have failed

- System modifications have changed flow characteristics

Sizing Guidelines

Proper sizing is crucial for effective operation. Consider these factors:

- Fixture Unit Values: Calculate based on connected fixtures

- Flow Rates: Match to maximum expected water flow

- Pressure Ratings: Select appropriate pressure capacity

- Physical Space: Ensure adequate installation clearance

Installation Best Practices

Location Selection

Optimal placement of water hammer arrestors is crucial for maximum effectiveness:

- Install within 6 feet of quick-closing valves

- Position vertically when possible

- Ensure accessibility for future maintenance

- Place at branch line endpoints

Professional vs DIY Installation

| Aspect | Professional Installation | DIY Installation |

|---|---|---|

| Cost | Higher initial investment | Lower upfront cost |

| Expertise | Guaranteed proper sizing | Risk of incorrect sizing |

| Warranty | Usually included | May void product warranty |

| Tools | Professional-grade equipment | Basic tools may suffice |

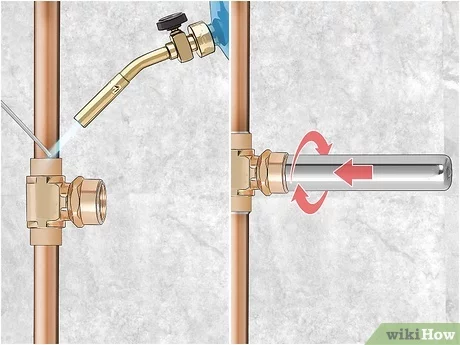

Installation Steps

- Shut off water supply

- Close main water valve

- Drain existing pipes

- Release residual pressure

- Prepare installation point

- Clean pipe surfaces

- Remove old arrestor if present

- Verify fitting compatibility

- Mount new arrestor

- Apply thread sealant

- Tighten to manufacturer specs

- Check alignment

- System testing

- Restore water supply gradually

- Check for leaks

- Test fixture operation

Maintenance Requirements

Regular Inspection Schedule

Implement a maintenance schedule to ensure optimal performance:

- Monthly visual inspections

- Quarterly operation tests

- Annual professional assessment

- Bi-annual pressure testing

Signs of Deterioration

Watch for these indicators of arrestor failure:

- Visible corrosion or damage

- Decreased effectiveness

- Unusual noises

- Water leaks around fittings

Alternative Solutions

System-Wide Approaches

When single arrestors fail to solve the problem, consider these alternatives:

- Pressure Reduction Valves: Install at main supply

- Multiple Arrestor Installation: Strategic placement throughout system

- Complete Pipe Securing: Enhanced bracing and support

- System Redesign: Modification of pipe layout

Modern Technologies

Recent innovations in water hammer prevention include:

| Technology | Benefits | Limitations |

|---|---|---|

| Electronic Arrestors | Precise pressure control | Higher cost |

| Smart Valves | Automated adjustment | Requires power |

| Flexible Connectors | Absorbs movement | Limited lifespan |

Prevention Strategies

Regular Maintenance

Implement these preventive measures:

- Schedule annual plumbing inspections

- Monitor water pressure regularly

- Address minor issues promptly

- Keep detailed maintenance records

System Modifications

Consider these long-term solutions:

- Install master pressure regulator

- Update outdated fixtures

- Replace aging pipes

- Add pipe insulation

Best Practices for Daily Use

To minimize water hammer risk:

- Close valves slowly

- Avoid simultaneous fixture use

- Maintain consistent pressure

- Report unusual sounds promptly

Professional Intervention

When to Call a Plumber

Seek professional help when:

- Multiple arrestors fail

- Persistent water hammer continues

- System pressure fluctuates

- Visible pipe damage occurs

Key Takeaways

A properly functioning water hammer arrestor is crucial for maintaining plumbing system integrity and preventing costly damage. Success depends on correct sizing, installation, and maintenance, combined with addressing underlying system issues.

Frequently Asked Questions

Q: How long should a water hammer arrestor last?

A: Quality water hammer arrestors typically last 5-7 years under normal conditions, though some may function effectively for up to 10 years with proper maintenance.

Q: Can water hammer damage pipes?

A: Yes, water hammer can cause significant damage, including pipe bursts, loose fittings, and weakened joints over time.

Q: Is it normal for a water hammer arrestor to make noise?

A: No, a properly functioning arrestor should operate silently. Any noise indicates potential problems requiring investigation.

Q: Can I install multiple water hammer arrestors?

A: Yes, multiple arrestors can be installed throughout a plumbing system, especially in larger homes or buildings with numerous fixtures.

Citations:

[1] https://mmlplumbing.co.uk/water-hammering/

[2] https://www.reddit.com/r/Plumbing/comments/3b3rv3/water_hammer_arrestor_not_helping/

[3] https://www.thespruce.com/solve-water-hammer-issues-844851

[4] https://www.geminivalve.com/water-hammer/

[5] https://www.oatey.com/faqs-blog-videos-case-studies/blog/how-do-water-hammer-arrestors-work

[6] https://aqueductplumbingcompany.com/plumbing/how-to-stop-water-hammer/

[7] https://www.timrauschplumbing.com/how-to-fix-water-hammer-in-plumbing-pipes

[8] https://www.measuremonitorcontrol.com/resources/water-hammer-causes-and-solutions